The cookie is used to store the user consent for the cookies in the category "Performance".

This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. The cookies is used to store the user consent for the cookies in the category "Necessary". The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". ROBOGUIDE provides engineers the tools needed to develop and test a complete robotic application in a simulation environment without the time and costs.

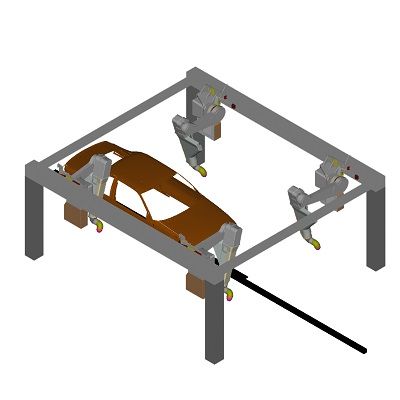

FANUC PAINT PRO SOFTWARE

The cookie is used to store the user consent for the cookies in the category "Analytics". FANUC Robotics’ ROBOGUIDE is the latest technology for off-line robot simulation software with a FANUC Robotics Virtual Robot Controller and full-featured robot programming. These cookies ensure basic functionalities and security features of the website, anonymously. Necessary cookies are absolutely essential for the website to function properly. Over 200,000 FANUC robots are installed worldwide.įor more information call (800) iQ-ROBOT, option 5, or go to. A subsidiary of FANUC LTD in Japan, the company is headquartered in Detroit and has facilities in Chicago Los Angeles Charlotte, North Carolina Cincinnati and Toledo, Ohio Toronto Montreal Aguascalientes, Mexico and Sao Paulo, Brazil.

After 26 years of success, FANUC Robotics maintains its position as the leading robotics company in the Americas. The company also provides application-specific software, controls, vision products, and complete support services. In addition, its compact size and ability to flip over and work behind itself maximizes flexibility for work cell design and saves valuable floor space.”įANUC Robotics America designs, engineers, and manufactures industrial robots and robotic systems for a wide range of applications including arc and spot welding, material handling (machine tending, picking, packing, palletizing), material removal, assembly, paint finishing, and dispensing. “It’s rated ‘best in class’ for speed and has one of the largest work envelopes in its class. “This is an exciting robot based on its capabilities and flexibility,” Wilson adds. Multiple mounting methods-including floor, ceiling, angle, and wall-make it possible for users to have better access to unusual work pieces. The six-axis M-710iC/50 SE is the latest member of the M-710iC robot series, which offers payloads ranging from 20 kg to 70 kg, and a reach of 1360 mm to 3110 mm. “In addition to the protective epoxy and air purge, we’ve incorporated coated bolts and double oil seals at the joints, making this a truly waterproof robot.” “The M-710iC/50 SE sets the benchmark for robots working in the super-harsh environments of die casting and foundry facilities,” says Virgil Wilson, product manager. In addition, the base of the robot purges air to avoid vapor entrance. The entire robot is coated with a special epoxy, and the wrist has protective covers to withstand high-pressure washing. Greenhouse Gas Emissions / Environmental Performance Data. FANUC News 2022-I (August 2022) Sustainability. FANUC Robotics America, Inc., recently introduced its M-710iC/50 SE FoundryPRO robot, IP67 protected for operation in the harshest environments. The three businesses of FA, ROBOT and ROBOMACHINE are unified with SERVICE as one FANUC, to provide innovation and reassurance to manufacturing sites around the world.

0 kommentar(er)

0 kommentar(er)